Pattern grading:

The way of resizing the master pattern is called "grading." In the apparel industry production patterns is generally made for medium size but if the buyer requires different size, then manufacturers have to grade the dimension like S, L, XL, XXL, etc. For example, if the sample pattern size is 10(M), then it must be made larger to accommodate sizes like 12(L), 14(XL) and 16(XXL) and to make smaller for sizes 8(S) and 6(YS).

The objectives of pattern grading is to properly increase or decrease the size of a master pattern, but keep up with shape, fit, balance, style and scale of the apparel. Pattern grading commonly used in apparel industry and fashion design sector.

Types of garment pattern grading techniques:

In the apparel manufacturing basic pattern grading methods are mainly divided into 2 types. They are

The desired range of sizes is created, one by one, using a pattern template. Marks are made around the master pattern at the appropriate distances and the marks the later joined up to form the enlarge pattern.

In this way a full set of templates, the “pattern set” is generated.

Grading machine:

A grading machine eases the task of creating the pattern set. The device grips the master or basic pattern and displaces it by a precise vertical and horizontal distance, after which the appropriate edge can be traced.

Now-a-days manual pattern grading methods are classified in 2 ways. These are mentioned and shortly describe in below:

a. Cut and Spread

b. Pattern Shifting

Computer based grading systems operate in one of two ways:

Once the pattern set has been generated on the computer, it may be used in various ways, depending on the level of automation in the factory.

Pattern grading is the process of manual or digital adjustment of your sample pattern from one size to another with the help of size specification chart and without changing the original style, initial look, and shape etc.

Pattern grading means the step wise increase or decrease of a master pattern piece to create larger or smaller sizes. The starting point can be smallest size or the middle size. Pattern grading alters the overall size of a design but not its general shape and appearance. Computer aided pattern grading system utilize internal calculation algorithms (grading rules) for pattern construction.

Pattern grading means the step wise increase or decrease of a master pattern piece to create larger or smaller sizes. The starting point can be smallest size or the middle size. Pattern grading alters the overall size of a design but not its general shape and appearance. Computer aided pattern grading system utilize internal calculation algorithms (grading rules) for pattern construction.

|

| Fig: Garment pattern grading |

The objectives of pattern grading is to properly increase or decrease the size of a master pattern, but keep up with shape, fit, balance, style and scale of the apparel. Pattern grading commonly used in apparel industry and fashion design sector.

In the apparel manufacturing basic pattern grading methods are mainly divided into 2 types. They are

- Manual pattern grading or two dimensional grading.

- Computer-aided pattern grading or three dimensional grading.

The desired range of sizes is created, one by one, using a pattern template. Marks are made around the master pattern at the appropriate distances and the marks the later joined up to form the enlarge pattern.

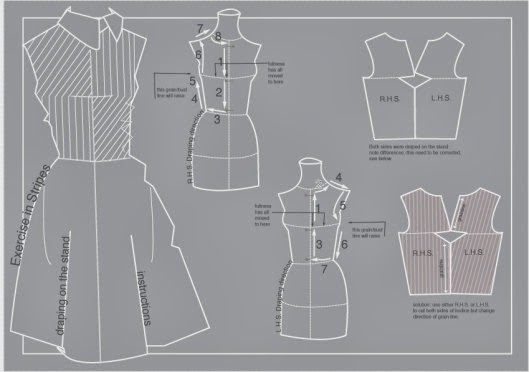

|

| Fig: Manual pattern grading |

Grading machine:

A grading machine eases the task of creating the pattern set. The device grips the master or basic pattern and displaces it by a precise vertical and horizontal distance, after which the appropriate edge can be traced.

Now-a-days manual pattern grading methods are classified in 2 ways. These are mentioned and shortly describe in below:

a. Cut and Spread

b. Pattern Shifting

a. Cut and Spread:

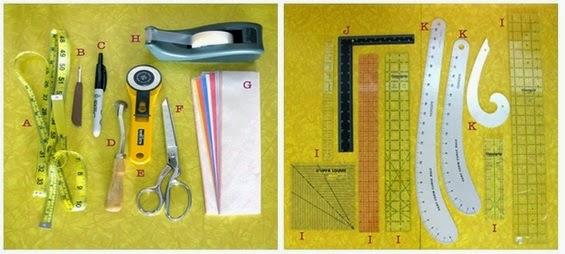

Cut and Spread grading method are starts by the use of tracing and marking techniques from the original master pattern to a white paper. Ensure that all the marking lines like grain line, darts are visible here. In this method original patterns are cut vertically into 3 parts and spread the cutting pieces by a specific amount to grade up. Then overlap them to grade down. To do this process, only scissors, a pencil, measurement tape, and a ruler is required.

b. Pattern Shifting:

Pattern shifting is another process of pattern grading. When pattern or fashion designer want to increase or decrease the overall dimensions of a pattern to get different sizes is called pattern shifting. To make the pattern larger, transfer the original pattern onto another sheet of paper. To make it smaller, they will have to trim the edges to the desired dimensions. It is done by moving the master pattern a certain measured distance up and down and left and right using a special designed ruler. To get the same result as the cut and spread method designer redraw the outlines.

Cut and Spread grading method are starts by the use of tracing and marking techniques from the original master pattern to a white paper. Ensure that all the marking lines like grain line, darts are visible here. In this method original patterns are cut vertically into 3 parts and spread the cutting pieces by a specific amount to grade up. Then overlap them to grade down. To do this process, only scissors, a pencil, measurement tape, and a ruler is required.

b. Pattern Shifting:

Pattern shifting is another process of pattern grading. When pattern or fashion designer want to increase or decrease the overall dimensions of a pattern to get different sizes is called pattern shifting. To make the pattern larger, transfer the original pattern onto another sheet of paper. To make it smaller, they will have to trim the edges to the desired dimensions. It is done by moving the master pattern a certain measured distance up and down and left and right using a special designed ruler. To get the same result as the cut and spread method designer redraw the outlines.

2. Computer-aided pattern grading:

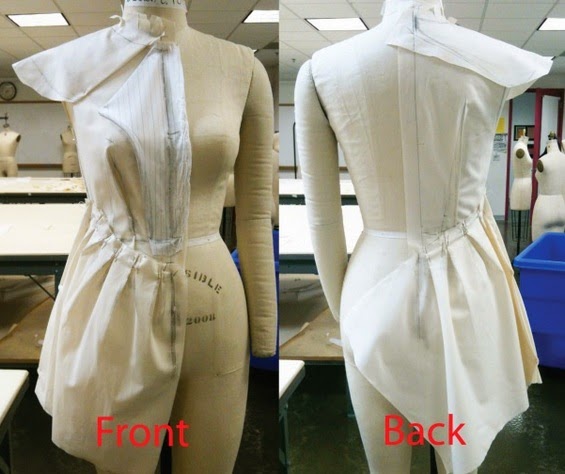

Computed grading (CAD) is the fastest pattern grading techniques. But when it first came, it was only used by larger fashion or apparel manufacturers for their production process. Now CAD is more affordable software. By this method every manufacturer’s get more accurate, precise, detailed patterns in a short time. |

| Fig: Computed pattern grading |

- The grading increments are feed into the computer and the different sizes are generated automatically using the same methods as applied for manual grading.

- The pattern for each individual size is calculated separately starting from the data in the size specification charts.

Once the pattern set has been generated on the computer, it may be used in various ways, depending on the level of automation in the factory.

In a fully automated system, the garment parts will be sorted automatically and arranged into a lay plan which can then be transmitted in the form of a control program to the automatic laying and cutting system. Alternatively, the patterns can be sent to a large plotting device where they will be drawn at full scale to serve as paper patterns for manual cutting. The patterns can also be used in an automatic device for cutting templates from more durable material.